Before You Buy a CNC

Real-World Insights From a Cabinet Shop Owner

Recently, I was reviewing some notes and reflecting on the process of purchasing our first CNC machine. At the time, I remember wishing for more resources for small shops making the switch to CNC. While there are thankfully now more resources and much has been written about it, it can still feel like a major step for a small shop.

Today, a nested-based CNC router is just about as prevalent in the shop as a tablesaw, but there are still many shops where the owner hasn’t chosen to invest in one. Perhaps they don’t think they have room. Perhaps they think it’s too expensive and the juice isn’t worth the squeeze. Maybe they think their shop is too small, either in sales or space, to justify the purchase. Maybe they’re just resistant to change. The purpose of this article is not to necessarily change your mind. We just want to share our experience and how it transformed our business.

I vividly remember sitting in a seminar at the International Woodworking Fair in 2008, where the speaker said, “You’re not really a serious cabinet shop if you don’t have a CNC machine.” Even though we were beginning to research CNC options at the time, this statement felt mildly offensive and took me aback. Years later, I now understand what the speaker was trying to emphasize. While it’s not necessarily a definitive statement, if you ask shops that have incorporated a CNC into their workflow, they will almost universally tell you it has had a major positive impact on their business. For us, I can hardly imagine going back to a shop without one.

Back then, we were a four man shop that mainly did residential work, with a few commercial jobs scattered in. We were looking to expand our shop’s throughput without significantly expanding our team, in keeping with our shop’s smart and lean philosophy. We had been exposed to the benefits of CNC technology by buying pre-cut parts, and it amazed us how much they improved our assembly speed. Additionally, we found ourselves with work that required us to farm out CNC work to other shops. All of this together set us on a path to purchase our own router.

Once we “took the plunge,” we immediately noticed that incredible new opportunities opened up for us. A year after we purchased the machine, we were able to take on a millwork project for the Atlanta Hawks locker room, something that would not have been possible without CNC. We also found that the machine paid for itself through contract work for other shops. The improvements to our own efficiency and productivity were the frosting on the cake.

This was our experience, but what about your shop? Are you thinking about a CNC machine? If you are, here are some things we learned from our experience for you to consider.

1 | Do you have room?

Sometimes you may realistically not have room. Some small shops are truly small. However, don’t look at a smaller space as a hindrance. Take the opportunity to look at the layout of your shop. Start with a blank slate and seriously consider your processes. How can you slot a CNC machine into the flow? Could this new machine eliminate another piece of equipment? Did your shop grow organically, with little thought to efficiency? Is there a sticking point in your shop that irritates you every time you work there? The possibility of increased efficiency and revenue from a CNC machine may justify expanding your space, either through remodelling or relocation. Regardless of whether you choose a CNC machine, every shop can benefit from better layout and workflow.

2 | Get Referrals

Do your own research, but I cannot overstate the value of referrals from other shops. Referrals will give you other people's actual experiences. Go to trade shows, call other shops in your region. In our area, our experience is that other shop owners were more than happy to share with us. Hopefully, you find it to be true for you as well.

3 | Don’t Focus on Stats Alone

Equipment manufacturers really like to emphasize their machines' performance stats. For instance, they may trumpet how fast the machine will move. Realistically, though, there are natural limits to how fast anyone can push a router bit through wood. The more important statistics are the speed when not cutting (rapid move) and the tool-change speeds. However, even these stats may not be as important in a small- to medium-sized shop where the machine may not even run every day.

In our case, we wanted a 5x12 machine but ended up buying one with a slightly slower rapid speed because it had a smaller footprint for the safety fences. The trade-off of a smaller footprint for slightly slower rapid speed has proven worth it for us.

4 | Buy for Sales and Support

When it comes to things like equipment and vehicles, a lot of hay has been made over brand distinctions and brand superiority. If we’re really honest, while the brand does matter somewhat, the single most important part of any purchase is your relationship with your salesperson and the support the company can provide. A great machine with poor after-purchase support is worse than a lesser machine with great support. The last thing you need in an emergency is to wait ages for a response or run into parts availability issues.

5 | Consider the Table Size

Bigger isn’t always better. The majority of cabinet shops will get along just fine with a 4x8 table. That said, if your shop does a lot of laminate, solid surface, or large millwork projects, a 5x12 table is a better choice. Don’t just think about what you’re doing now; consider where you want to be in five years. If you buy only for your current needs, you may regret it later as your business expands.

6 | Infeed and Outfeed

Another thing to consider is how you’ll get material into the machine and parts out of it. In our shop, to save our backs, we chose a vacuum lift to load the machine. This enables a single operator to load heavy sheets of material singlehandedly. Many machines will offer an autoloader infeed table option. For us, sacrificing the floor space wasn’t worth it to save a few minutes in the process. An outfeed table or unloading system is more important. We’ve found that this allows the operator to perform secondary operations, such as labeling, edgebanding, or pocket drilling, while the machine is cutting the next sheet.

7 | Software

Software is the heart of the CNC machine, and many of the frustrations of implementing CNC are software-related because the learning curve for software is often steeper than that of the machine itself. This is one of the most important decisions you will make regarding CNC automation. Choose a software platform that you can grow with. Rarely will the software that ships with your machine completely fit your needs. For a cabinet or millwork shop, a more robust software suite is usually necessary. Consider your needs. You may need two different pieces of software to cover all of your shop processes. One that specializes in cabinet production and another for custom pieces like furniture, conference tables, or hardwood processing. In our case, we had already been using a leading software brand to generate drawings and cutlists, and while we tried several other less expensive options, we ultimately chose to stay with what we were familiar with for the cabinet manufacturing and added a different program for the non-cabinet parts.

Secondly, really lean into training on your specific software. As I mentioned before, the learning curve is steep, so training is vital. Sometimes, training lessons come with the software. If they’re not included with your purchase, try to negotiate to have them included, or at least get a discount on training. You will likely find that training will be absolutely worth the investment.

8 | Plan for Power and Air

CNC machines require a significant amount of both electrical power and air. Proper planning in both instances can save you money and help you avoid problems down the road.

When it comes to power, guesswork won’t cut it; consult with an electrician to ensure it's right. Improper or inadequate power connections can stall out the installation process. In fact, the setup is often included with the machine purchase, but if the installer finds that the electrical connection isn’t right, he’ll have to go home without setting up the machine.

In our instance, our shop is in a rural setting, and three-phase power isn’t readily available. The electronics in a CNC machine require a super stable power supply, so we had to purchase an electronic phase converter. We received two quotes for the electrical work at our shop, and one quote was $40k higher than the other. The company with the higher quote recommended that we upgrade our service, get new transformers, and make other major changes. The other company took the time to really try to understand our processes. They asked us how many machines we ran at once and made recommendations to allow us to retain our existing electrical service. Years later, and after several machine upgrades, we are still using the same service.

Regarding air supply, if you already have a robust air system in place, you may be okay. Review the demands of your particular CNC machine and evaluate what you have. Most piston air compressors have a duty cycle of only 50%, which may not be sufficient to run a CNC. We’ve found a screw-type compressor to be the best option for our shop.

With any air system, moisture is a killer, so a dryer is an absolute must-have. For a high-demand system that requires completely clean, dry air, such as a CNC machine, a regenerative air dryer is the best option. Side note: this type of air supply will be best for your finish room as well.

When it comes to power and air, do your research, get multiple quotes, and ask around for recommendations from other shops in your area.

9 | Don’t Get Dusted

A CNC machine can really make the dust fly, so it is often necessary to upgrade your dust collection system. As with many other things listed here, think ahead to where you want to go and purchase a system that will support your shop in the long run. You may find that spending money now can save you money down the road.

10 | Tool Tips

As with so many other aspects of this article, where you get your tooling from is as important as what you get. The size of the tooling company is less important than the knowledge and accessibility of the sales team. A smaller company may not be able to compete on price, but it may have substantially better customer service. Again, do your research and ask around. Be sure to have all of your tooling, tool holders, and your tool changer on hand before the setup technician arrives. This will enable them to set up and calibrate everything in one go.

*Pro Tip: Once you’re up and running, batching your tool sharpening may save setup time in the long run.

11 | Part Labeling

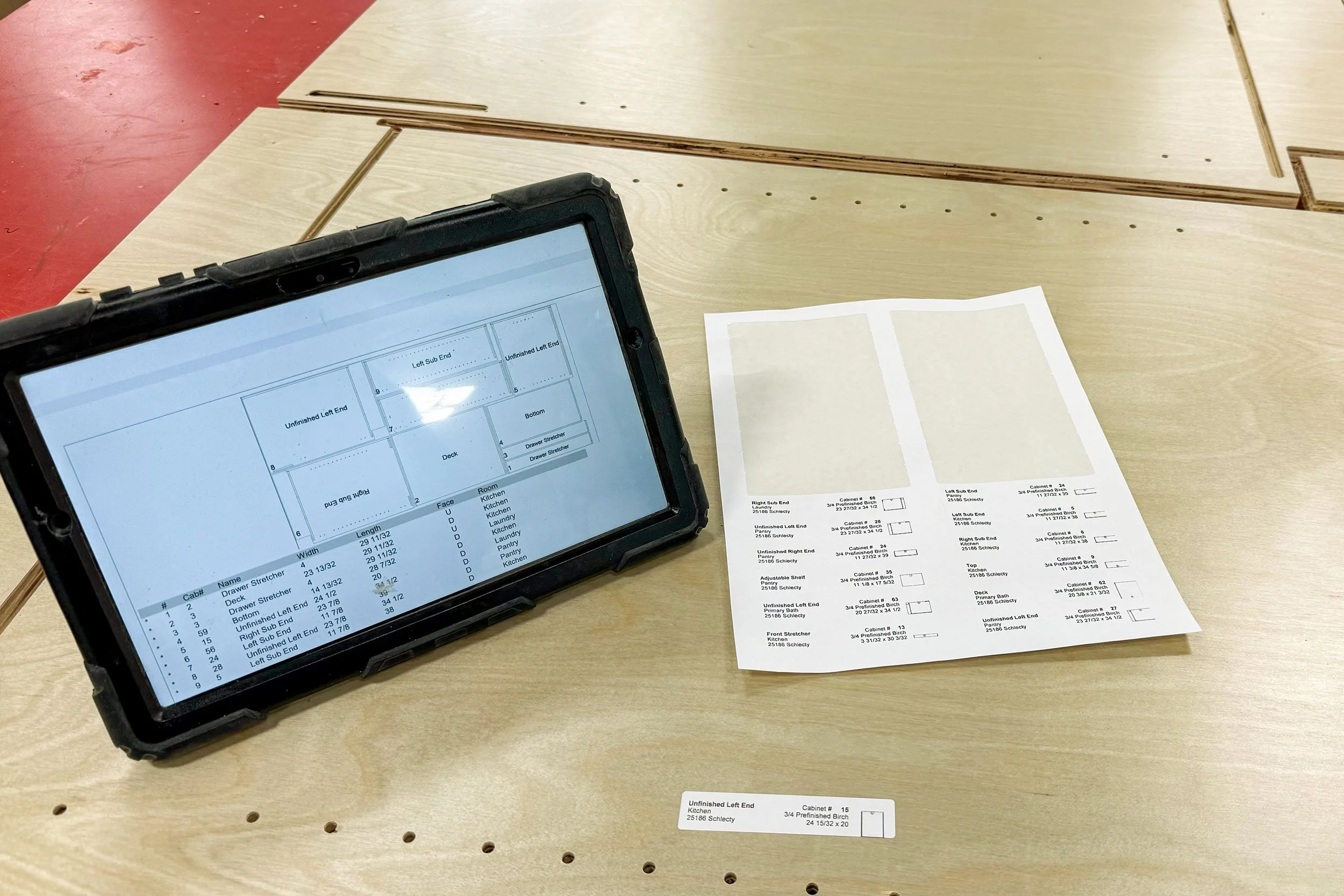

In CNC production, it is critical that parts be labeled, one way or another. It is simply too hard to keep track of everything otherwise. Some high-end machines have built-in labelling done during or before the cutting process, but this feature may be out of reach for a small or mid-sized shop like yours. In our shop, we’ve found that printing the labels and having the operator add them on the outfeed table is the most cost-effective process for us. We’re a paperless shop, so the sheet layouts are on an iPad at the outfeed station, making the labeling process really easy. Once labeled, our operator places the parts vertically on a cart, grouped by cabinet number, ready for assembly.

12 | Production Efficiencies

One common thread throughout this article is that incorporating a CNC machine into your shop can offer additional benefits that may not be obvious at first glance. In our shop, we found that implementing a CNC helped us rethink some processes and further standardize our construction methods and materials. For example, we chose to make our unfinished ends out of the same material as our adjustable shelves and partitions. This helped with material yield and reduced our material SKUs.

In conclusion, there are as many methods of cabinet construction as there are cabinet shops, so take our experiences with automation for what they are. Your experiences may differ, but as long as you endeavor to enjoy the process, you will find it to be an exciting time. Growth is never easy, nor is it painless, but I’ve never heard of a shop that has endeavored to grow and regretted purchasing a CNC machine.